11/09/2023

The Importance of Quality and Safety in Scaffolding: The Role of Advanced Materials and SLV Group’s Innovations

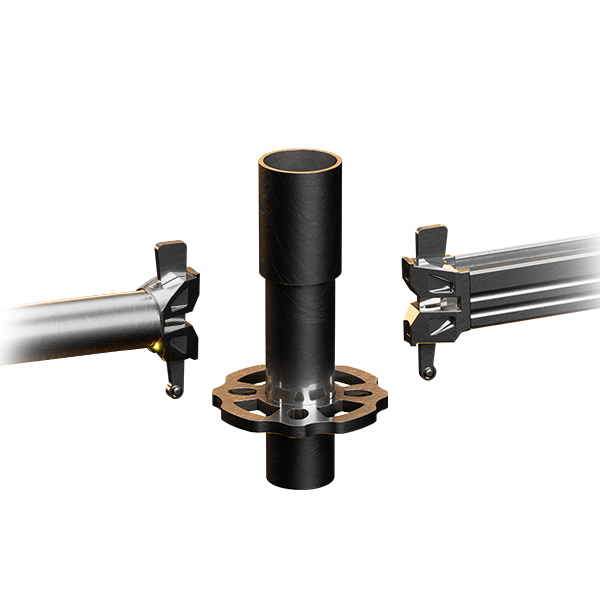

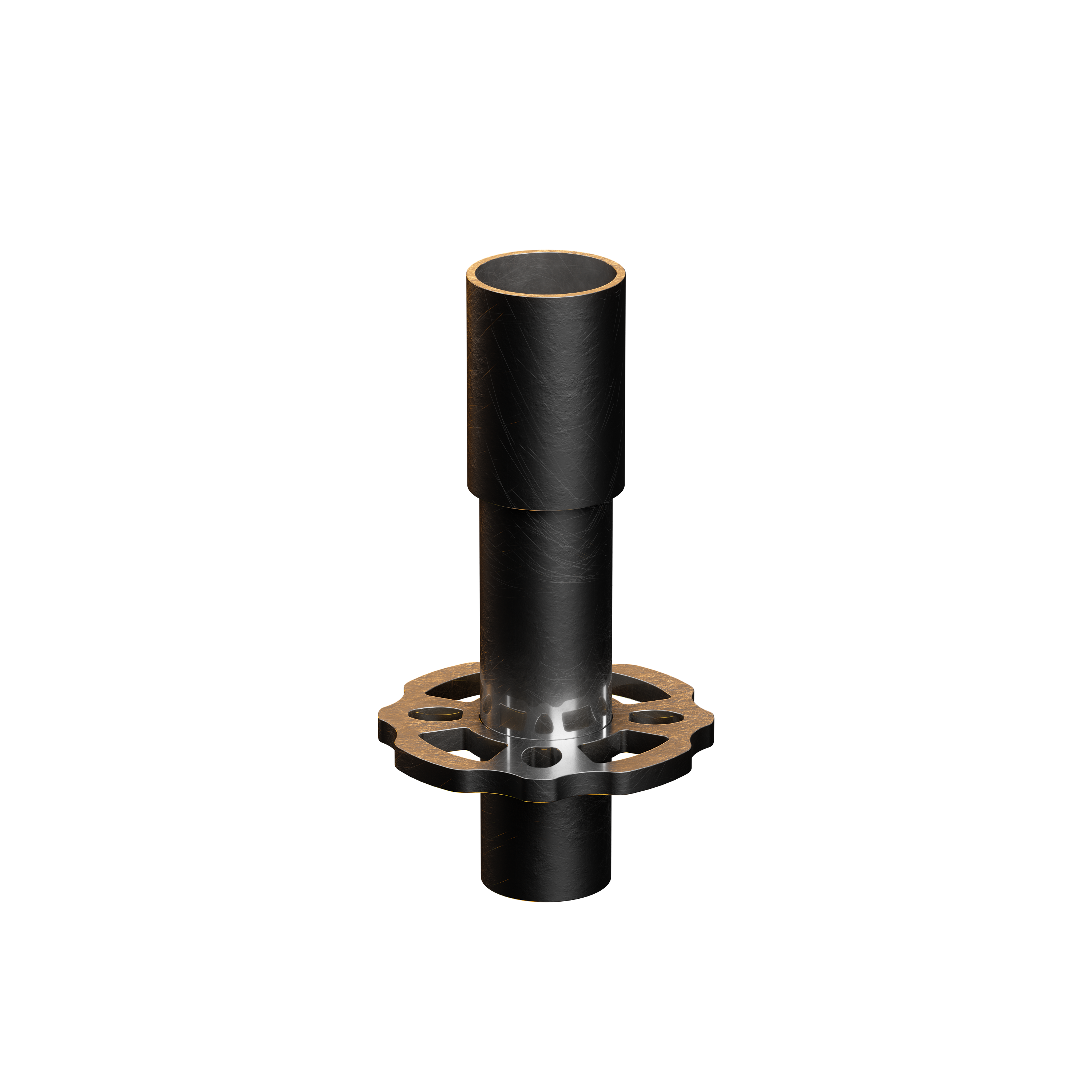

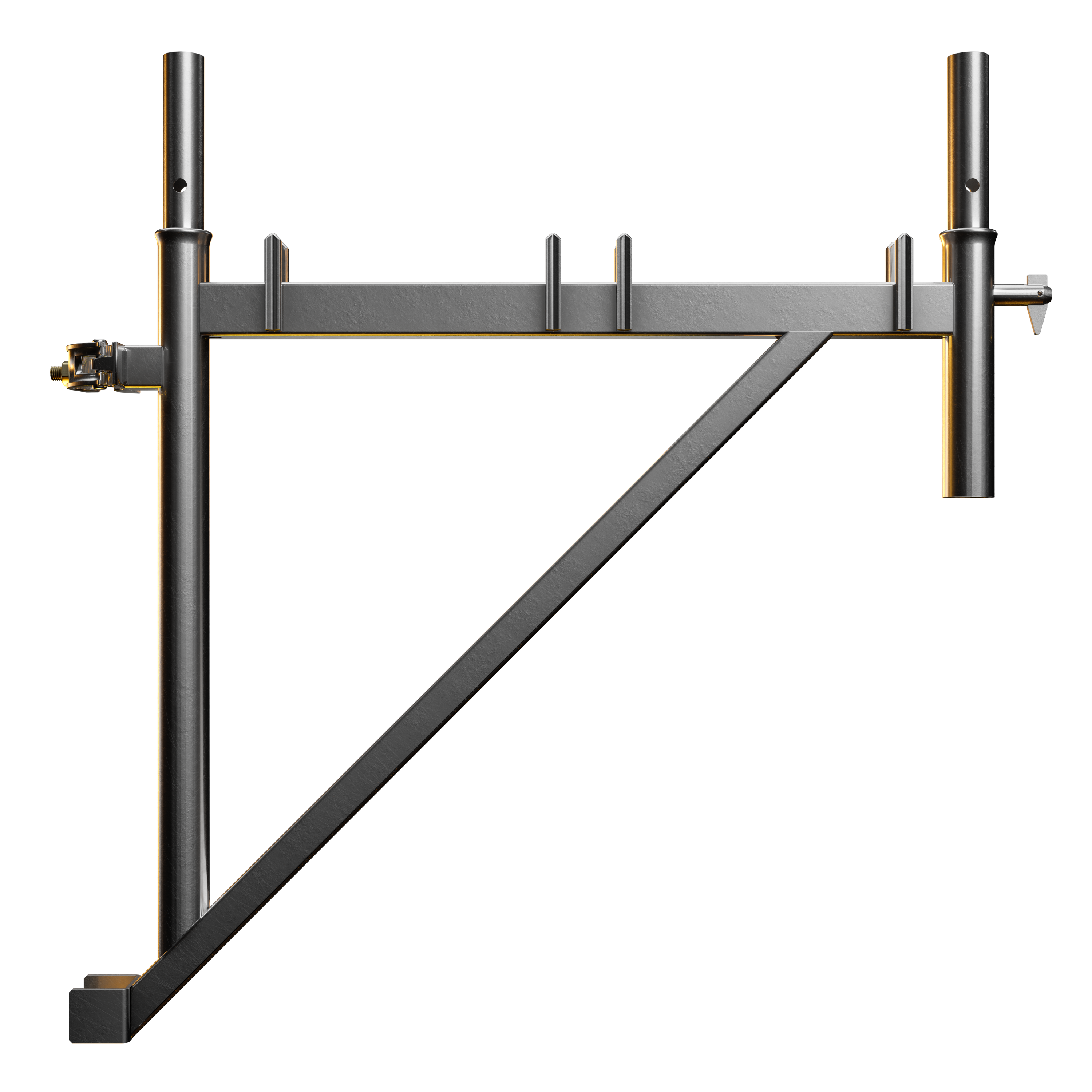

The quality and safety of materials used in scaffolding are paramount to the success of construction and maintenance projects. High-quality materials such as steel, aluminum, and composites enhance safety, durability, efficiency, and compliance with industry standards. The SLV Group, a Polish pioneer in scaffolding technology, exemplifies the benefits of using the best materials and the latest technology to create scaffolding systems that meet and exceed industry expectations. As the construction industry continues to evolve, the importance of quality and safety in scaffolding remains steadfast, making companies like SLV Group integral to its progress.